Step into many modern residential or commercial buildings today, and you may notice something subtle, yet telling: the elevator feels less like a utilitarian compartment and more like a thoughtfully designed interior space. Instead of cold, uniform metal, there’s warmth, texture, and a sense of crafted detail. That’s the result of a growing trend: mixed-material elevator interiors, where wood, metal, and stone (or stone-look finishes) combine to create a cabin that’s visually rich, durable, and surprisingly efficient.

This approach is proving to be a go-to solution for property owners and facility managers who want to elevate the aesthetic and functionality of their buildings, without the cost, weight, and disruption of traditional full-scale renovations.

Why Mixed Materials Make Sense: More Than Just Looks

Mixed-material design isn’t just about style. It works because it leverages the strengths of different finishes to meet real needs:

- Wood (or wood-look finishes) lends warmth, softness, and a sense of comfort that metal alone rarely delivers. It humanizes the space: especially important in residential buildings or hotels where first impressions matter. According to elevator-interior design guidelines, wood paneling remains one of the most effective ways to add refinement and character to a cab interior.

- Metal, used on doors, trim, or accent features, offers robustness, fire resistance, and longevity. Brushed or textured metal finishes deliver modern, clean lines and stand up to heavy use.

- Stone or stone-look finishes contribute visual gravitas and a sense of permanence. When real stone is impractical, heavy, costly, complex, high-quality stone-look vinyl or panels offer a practical alternative: the same aesthetic impact with much less weight, cost, and installation complexity.

By combining these materials thoughtfully, wood-grain walls for warmth, metal doors or accents for durability, and stone-look finishes in lobby areas or flooring, you get a cabin that doesn’t just move people from floor to floor, but reinforces the building’s identity and quality.

Mixed-Material Elevator Trends: What the Industry Is Doing Now

Elevator interior specialists and manufacturers increasingly highlight mixed-material claddings as a top solution for 2026 and beyond. Rather than selecting a single uniform material, building owners and designers are now specifying combinations that reflect a building’s style, from luxury residential towers to boutique offices.

This shift is driven not just by aesthetics, but by practical advantages: mixed materials can strike a balance between cost, weight, durability, and design impact. Laminates, decorative panels, vinyl wraps, and engineered claddings deliver wood, metal, or stone looks, but remain light, easier to install, and far less disruptive than real wood or stone installations.

Importantly, these solutions are compatible with high-traffic buildings: cabs in condos, hospitals, hotels or corporate towers that see dozens (or hundreds) of rides per day. With proper materials, mixed-material cabins prove long-lasting, low-maintenance, and still visually striking.

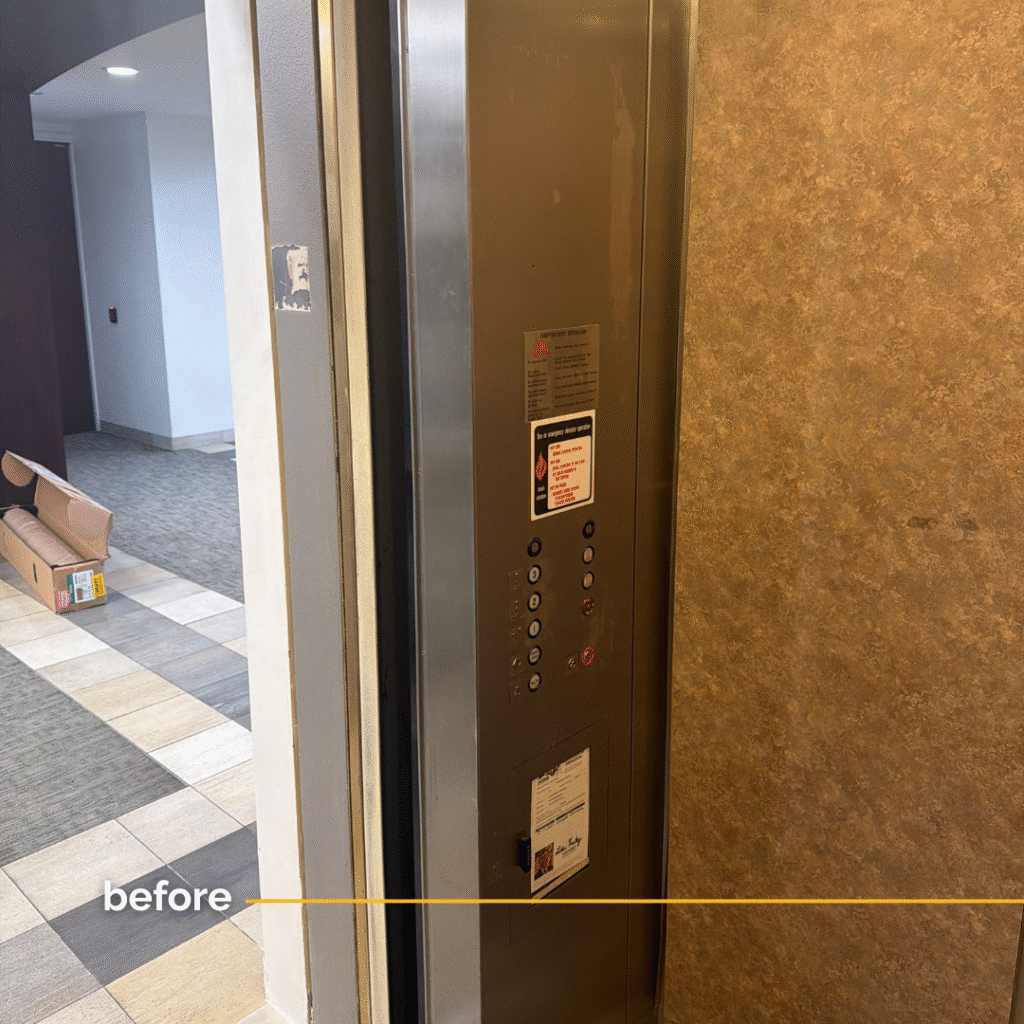

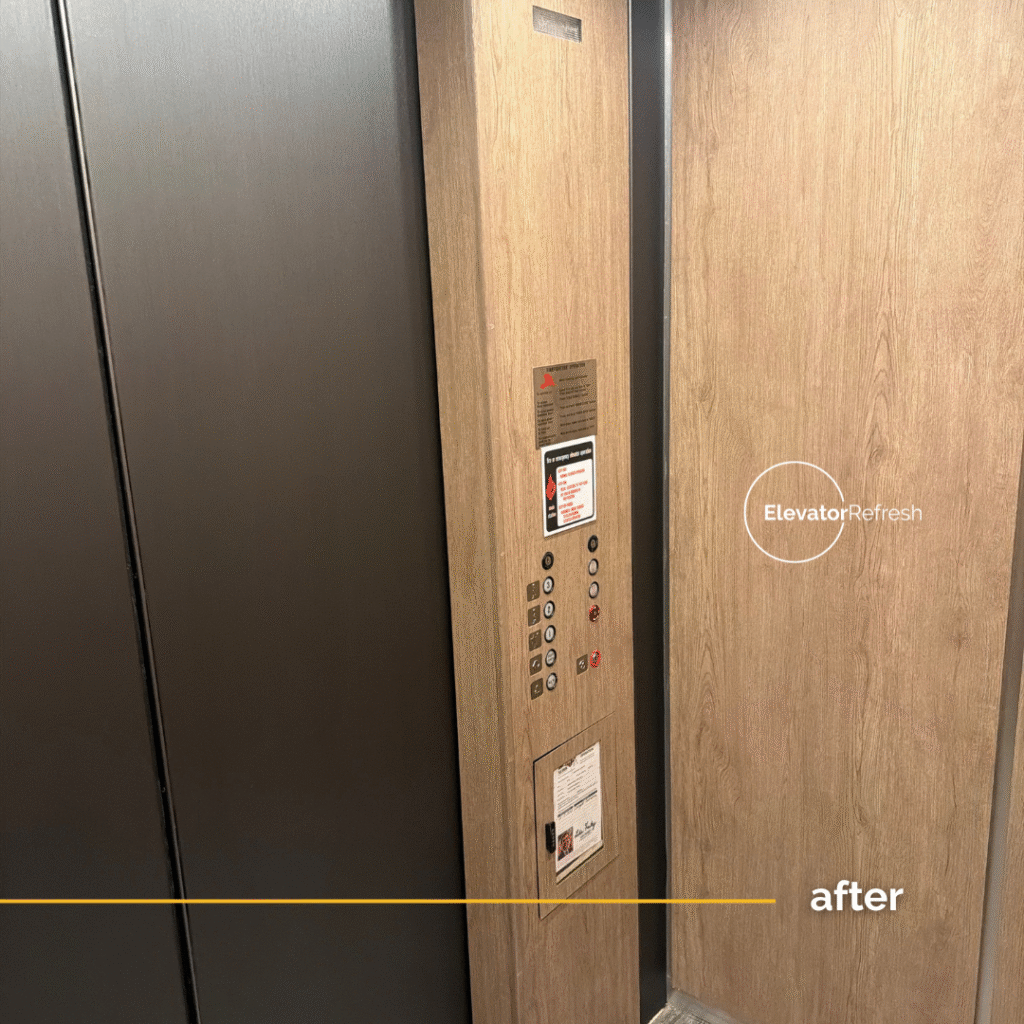

Real-World Success: Case Study from a commercial building in Charlotte

One of the best demonstrations of mixed-material renovation done right comes from a recent project at a commercial building. In that project, the entire upgrade was completed without replacing the elevator shell, instead using architectural film and modern finishes to transform two cab interiors, their two landings, and even the lobby’s granite slab between elevators.

What Was Done

- Cab walls and panels were refinished with wood-texture film (pattern “Split Wood”), replacing the old plain finishes and creating a warmer, more inviting cabin.

- Doors, trims, and hardware received brushed/metallic finishes (pattern “Tarnished Silver”), giving a contemporary, durable look appropriate for a high-use building.

- Lobby area and granite slab between elevators were refreshed with a bronze-patina finish, harmonizing the elevator experience with the building’s shared spaces.

Results & Benefits

- The transformation delivered a cohesive design aesthetic: warm wood, sleek metal, refined lobby finishes, a true mixed-material interior that feels intentionally designed.

- The work avoided heavy demolition, major structural changes or long elevator downtime, a crucial advantage for an occupied office building.

- The renovation cost was significantly lower than what a full natural-material refit (real wood + stone) would demand. According to the project summary, the cost savings were substantial while delivering a “like-new” appearance.

- The project underscores how architectural films and modern cladding solutions can deliver high-end finishes with pragmatic constraints: limited weight, fire-rating compliance, minimal downtime, and reduced waste. This aligns with broader industry best practices for elevator interior renovation.

This case makes it clear: mixed-material elevator renovations aren’t hypothetical or niche, they’re real, practical, and effective in active buildings.

Why Mixed-Material Renovations Often Outperform “Natural-Only” Rebuilds

When considering renovation of an older elevator cab, traditional approaches might suggest tearing out walls, installing real wood paneling, perhaps stone flooring, metal doors, a heavy, expensive, disruptive job. Mixed-material finishes challenge that model in several key ways:

- Cost & Time Efficiency: Engineered cladding, vinyl wraps, and decorative panels cost less and install faster than sourcing, cutting, and installing natural wood or stone. According to market sources, vinyl- or film-based renovations can save a significant portion of the budget while delivering comparable visual quality.

- Structural and Weight Considerations: Natural stone or thick wood add considerable weight, a problem in elevator cabins that must meet strict load limits. Mixed-material films and laminates are lighter and avoid structural complications.

- Durability and Maintenance: Mixed finishes, especially those designed for elevator use, resist wear, scratches, moisture, and daily contact better than bare or untreated natural surfaces. That reduces long-term maintenance and extends the cabin’s useful life.

- Flexibility and Adaptability: Vinyl and laminate claddings allow for design adaptability. If tastes change, finishes can be updated more easily than natural wood or stone, making future renovations simpler and more cost-effective.

In many cases, mixed-material renovation hits the sweet spot: beautiful, durable, and cost-effective.

Planning a Mixed-Material Elevator Renovation: What to Consider

If you’re thinking about upgrading your elevator interiors, here’s a practical path:

- Evaluate the existing cab: check condition of walls, doors, ceiling, structural load capacity, and compliance requirements.

- Define your visual goal: do you want a warm residential feel, a sleek corporate look, or a luxurious lobby-to-cab experience?

- Choose appropriate materials: consider wood-look laminates or films for walls, textured metal for doors and trims, and stone-look finishes for flooring or lobby areas. Make sure materials meet fire, durability, and code requirements.

- Plan for minimal disruption: many mixed-material renovations (using film/laminates) can be done in a day or a weekend, avoiding long elevator shutdowns.

- Coordinate with common areas: synchronize elevator cabin finishes with lobby, corridors, and building design to maximize cohesive aesthetic impact.

- Factor long-term maintenance & adaptability: choose finishes that are easy to clean, resist wear, and can be updated or refreshed if needed without full demolition.

Conclusion: Mixed Materials – A Smart, Balanced Path Forward for Elevator Interiors

Mixed-material elevator interiors, combining wood warmth, metal strength, and stone’s tactile or visual weight, represent a mature, balanced approach to modernization. They deliver high-end aesthetics, operational practicality, lower cost and shorter downtime.

The success story at the commercial building shows this is not a theoretical best practice, it is a proven, real-world solution. For building owners, property managers, and designers seeking lasting value and refined interior experiences, mixed-material elevator renovation offers one of the best returns on investment in vertical-transport upgrades.

If you’re considering upgrading your building’s elevators, exploring a mixed-material design could be the key to achieving sophistication, durability, and efficiency, all at once.