When planning an elevator upgrade, most building owners and managers focus on design, color, and cost. While these factors are important, there’s one element that often gets overlooked, but has the greatest long-term impact:

Material quality

The material you choose for your elevator’s new finish doesn’t just determine how it looks. It affects durability, safety, maintenance, tenant satisfaction, and even project timelines.

At Elevator Refresh, we’ve seen firsthand how the right (or wrong) material choice can make or break an elevator renovation project.

Why Material Quality Should Be Your First Priority on Elevator Refinishing

When refinishing an elevator, you’re working in a high-traffic, high-contact environment:

- Tenants and guests use the elevator multiple times a day.

- Cabs are subject to scuffs, bumps, and scratches.

- Safety codes and fire ratings must be met or exceeded.

Choosing the wrong material can lead to:

- Premature wear and tear

- Frequent repairs or full replacements

- Compliance issues with local safety regulations

- Extended downtime for maintenance

The right material should offer more than just a great look, it should perform under pressure.

Key Features to Look For in Elevator Refinishing Materials

Here are the essential qualities any premium elevator finish should have:

- Fire Safety

The material must be fire-rated and meet strict safety standards. This protects not only the building but also its occupants.

- Durability & Impact Resistance

Elevator surfaces need to withstand constant use without showing signs of damage.

- Waterproof

Moisture resistance is critical, especially in humid climates or commercial spaces like hotels and hospitals.

- Stretchable & Moldable

Elevators often have curves, corners, and irregular surfaces. A stretchable material ensures a perfect fit and seamless finish.

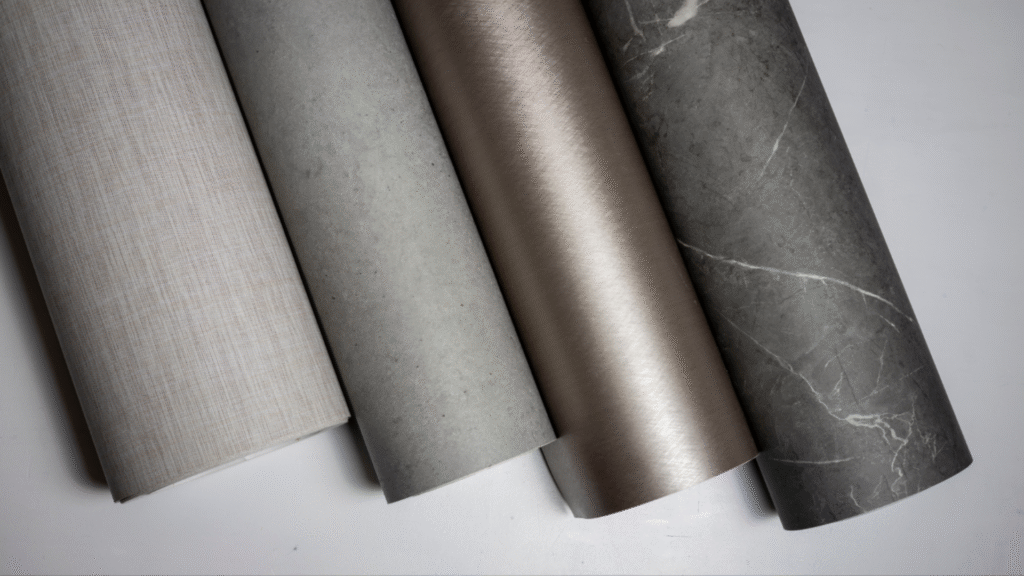

- Wide Range of Patterns & Textures

Design flexibility is important. From wood grain to marble, metal, and solid colors, the material should offer options that suit the building’s aesthetic.

- Short Lead Times

Fast project turnaround depends on having materials readily available without long waits.

Why We Choose Bodaq Architectural Film

At Elevator Refresh, we’ve tested many materials, and our choice for premium elevator refinishing is Bodaq Architectural Film.

Here’s why:

- Fire-rated to meet strict safety codes.

- Waterproof and easy to clean.

- Stretchable and moldable, adapting to complex surfaces.

- Hundreds of patterns and textures, including wood, marble, metal, leather, and stone.

- Short lead times, reducing project delays.

- Designed for long-term durability in commercial settings.

Bodaq film not only deliver exceptional performance but also allow us to create stunning, customized designs for every client.

The Bottom Line: Material Matters

A beautiful design means little if the materials can’t stand up to real-world use.

By choosing high-quality materials like Bodaq Architectural Film, building owners and managers can ensure their elevator renovations are:

- Safe

- Durable

- Low-maintenance

- Visually impressive for years to come

Thinking About Refinishing Your Elevator?

At Elevator Refresh, we combine expert application with high-performance materials to deliver elevator interiors that are not just attractive, but also durable and easy to maintain. We work exclusively with Bodaq architectural film, a premium surface solution known for its fire-rated performance, antimicrobial protection, water resistance, and wide range of design options.

To help you visualize the transformation, we offer mock-ups using your own elevator photos. For a more immersive preview, optional 3D renderings are available as an add-on, ideal for stakeholder presentations or design approval.

If you’re ready to upgrade, Elevator Refresh makes the process simple, fast, and cost-effective. Contact us to explore design options and discover how we can transform your space.