If you’ve ever walked into a recently built commercial tower, whether a corporate office building or a high-end hotel, you might have noticed a subtle but distinct change in elevator interiors. The era of mirror-finish stainless steel cabins is receding. In its place, a more refined, understated, and practical aesthetic is emerging: matte and anti-fingerprint finishes.

For property owners and facility managers planning elevator renovations, this shift reflects more than just style, it’s about maintenance, durability, visual comfort, and long-term cabin upkeep. Matte and textured surfaces are increasingly seen as a practical alternative to glossy metal, offering multiple operational advantages.

Why Glossy Metal Is Being Reconsidered

Traditionally, elevator interiors relied on polished stainless-steel panels: sturdy, corrosion-resistant, and for many years the standard for elevators. However, in high-traffic buildings, offices, residential towers, hotels, these surfaces begin to show their flaws over time:

- Glossy panels easily expose fingerprints, smudges, oils, and scratches, marks that require frequent cleaning and maintenance.

- In cabins with LED or bright artificial lighting, reflective surfaces often cause glare or unwanted reflections, reducing visual comfort.

- As wear accumulates, the once-pristine look deteriorates, which can degrade the perceived quality of the building.

Because of this, many modern renovation projects are rethinking their material choices, opting for surfaces that are less reflective and more forgiving in daily use.

What Matte or Anti-Fingerprint Finishes Bring to the Table

Durability and Better Hidden Wear

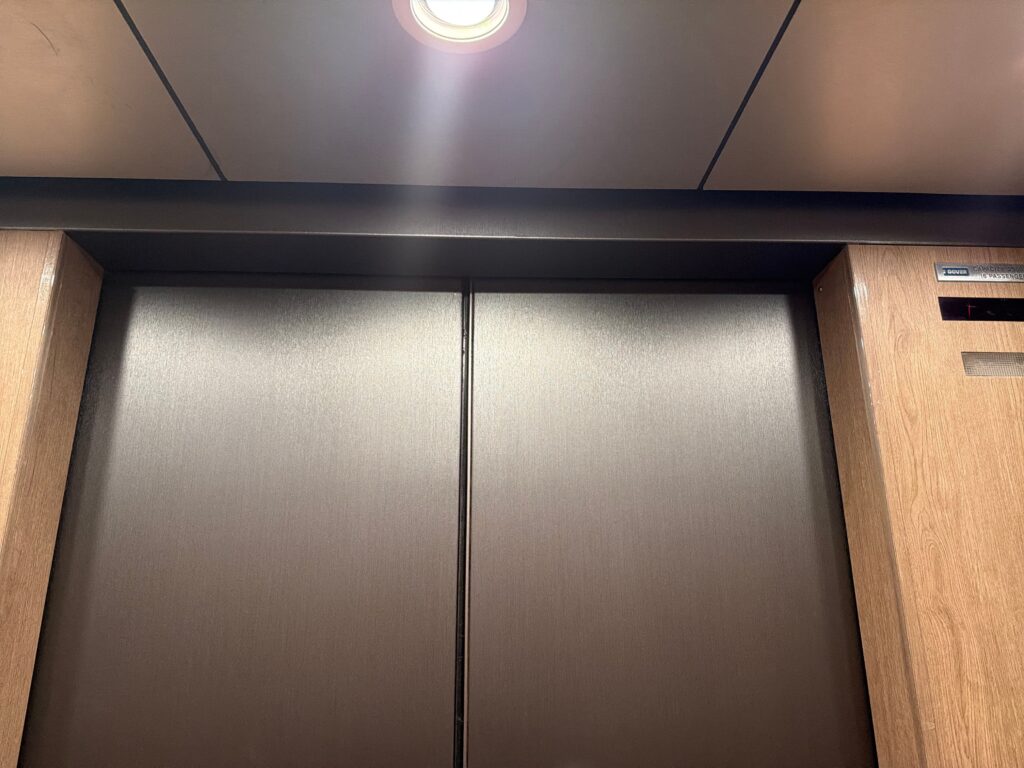

Alternatives such as high-pressure laminates, rigid vinyl finishes, textured metal, or decorative surface coatings offer solid resistance to abrasion, impacts, and regular use. In many cases, these finishes are better at concealing minor scratches or marks than polished metal, meaning the elevator cabin keeps a uniform look for longer. Industry sources on elevator-interior materials point out that textured or matte finishes tend to age more gracefully under heavy use. See the stunning results of this metal-on-metal transformation here.

Reduced Maintenance and Easier Cleaning

Because fingerprints, oils, and smudges aren’t as visible on matte surfaces, cleaning routines can be simplified. Rather than frequent polishing or aggressive cleaning to maintain shine, maintenance staff can focus on basic cleaning, reducing workload and cleaning costs over the elevator’s lifetime. This is particularly relevant in buildings with heavy traffic – like multifamily housing, offices, hotels, or medical facilities, where frequent cleaning is both costly and disruptive.

Flexible Aesthetics with Multiple Material Options

Matte and textured finishes offer a wider design palette beyond metal. Materials like laminates, vinyl, textured metals or decorative coatings can mimic wood grain, stone, brushed metal, or plain matte solids. This flexibility enables elevator interiors to harmonize with lobby, corridor, and overall building finishes, achieving a cohesive design without heavy structural changes.

Better Integration with Modern Lighting and Flooring

Modern elevators increasingly use LED lighting and contemporary flooring solutions such as vinyl tiles or other resilient materials. In this context, non-reflective walls and doors help control lighting balance, reduce glare and visual noise, and create a calmer, more sophisticated cabin ambience. Textured surfaces also pair well visually with stone-look or matte floors, giving a more modern, unified interior.

When Matte/Textured Finishes Make More Sense Than Polished Metal

Choosing matte or textured finishes over polished metal is particularly sensible when:

- The elevator serves high-traffic environments (residential towers, hotels, hospitals, commercial buildings).

- The goal is to reduce maintenance efforts and preserve a clean appearance longer.

- The building’s interior design favors contemporary, minimalist, or natural aesthetics, where subtlety and texture are more aligned than shine.

- There is a desire to match elevator finishes to hallways, lobbies, and overall architectural finishes for consistency.

In lower-traffic or more aesthetic-focused cases, glossy metal may still have appeal, but the trade-offs should be carefully considered.

Overview of Alternative Materials: Pros and Cons

Laminates & Decorative Vinyls

These materials are widely used for elevator renovations due to their variety, cost efficiency, and relative durability. They tend to be lightweight, easy to install, and provide a broad range of finishes, from wood-like to stone or solid colors, offering flexibility in design.

Textured or Brushed Metals

Instead of mirror-polished stainless-steel, textured metal finishes (brushed, matte, or mild grain) provide greater resistance to visible scratching and fingerprints, while retaining metal’s structural robustness. These finishes are often specified in modern elevator design guidelines when combining durability with aesthetics.

Vinyl or Resilient Flooring (LVT, etc.)

For elevator floors, lighter flooring materials such as LVT (luxury vinyl tile), resilient vinyl, or other composite floorings have advantages: lower weight, ease of installation, slip resistance, and a wide range of aesthetic options (stone-look, concrete-look, neutral tones). These are especially appropriate when paired with matte or textured walls and doors, offering a cohesive, modern cabin environment.

How to Evaluate and Specify Elevator Renovations with Matte/Textured Finishes

When planning a renovation using these alternative finishes, consider:

- Usage intensity: If the elevator is in a high-traffic building, prioritize materials with high abrasion and impact resistance.

- Design context: Match finishes to lobby, hallway, and building interior finishes for consistency.

- Maintenance expectations: Plan for simpler, lighter cleaning routines rather than frequent polishing or deep cleaning.

- Weight and structural constraints: Especially relevant in older elevator systems where extra weight could strain load capacity; lighter laminates and vinyls can help avoid such issues.

- Longevity and aesthetics: Consider how finishes age under use, and choose materials that hide wear over time.

- Budget vs. benefit: Alternative finishes often offer significant savings compared to full-scale panel replacement, while delivering similar or better visual and operational performance.

Conclusion: Matte & Textured Surfaces: A Practical, Long-Term Alternative

Using matte or textured finishes for elevator interiors is more than a design trend, it’s a response to real operational needs: maintenance reduction, durability, visual comfort, flexibility, and cost-effectiveness.

For many buildings, whether residential, commercial, or hospitality, these alternatives provide a smart balance of aesthetics and performance. If your property needs an elevator upgrade or renovation, considering matte or textured finishes should be part of the evaluation.