Scratches are inevitable in elevator interiors, especially in commercial and residential buildings where traffic is constant. From rolling luggage and carts to keys, cleaning tools, and pets, elevator cabs endure daily friction that slowly wears down surfaces and affects the building’s overall aesthetic.

But what if you could restore a scratched elevator interior without replacing a single panel?

Welcome to a smarter approach: resurfacing your elevator with architectural vinyl film.

Why Scratches in Elevators Are a Bigger Problem Than You Think

First impressions matter. An elevator with scuffed walls, dull metal, or stained laminate doesn’t just look bad, it signals neglect. For hotels, offices, or apartment buildings, this can:

- Decrease tenant satisfaction

- Damage brand perception

- Lower property value

In many buildings, elevators are the most frequently used interior space. Maintaining their appearance is key to maintaining user trust and comfort.

Common Causes of Elevator Scratches

Even with careful cleaning and maintenance, these materials are prone to scratching:

- Stainless steel: shows fingerprints and fine scratches easily

- Wood laminate: chips at edges and scuffs from impact

- Painted panels: prone to flaking and surface damage

High-traffic buildings (especially hotels, hospitals, residential towers, and commercial centers) see accelerated wear.

Traditional Fix: Replacement or Repainting

Historically, fixing scratched elevator interiors meant:

- Removing and replacing wall panels

- Repainting or refinishing surfaces

- Coordinating permits, downtime, and inspections

This approach is:

- Expensive (costing $20K–$50K per cab)

- Time-consuming (1–3 weeks of downtime)

- Disruptive to tenants, guests, or staff

The Smart Alternative: Resurfacing with Elevator Refresh

Elevator Refresh offers a better solution: wrapping the existing elevator panels with scratch-resistant architectural vinyl film.

This process:

- Covers existing scratches

- Prevents new damage

- Modernizes design instantly

- Takes only one day to complete

- Budget friendly at $5k-$10k per cab

We use Class A fire-rated and UL 10B/10C tested products trusted by property managers and hospitality designers around the world.

Available in over 450 finishes, from brushed metal to matte woodgrain, our material mimics premium textures while adding a protective layer against daily wear.

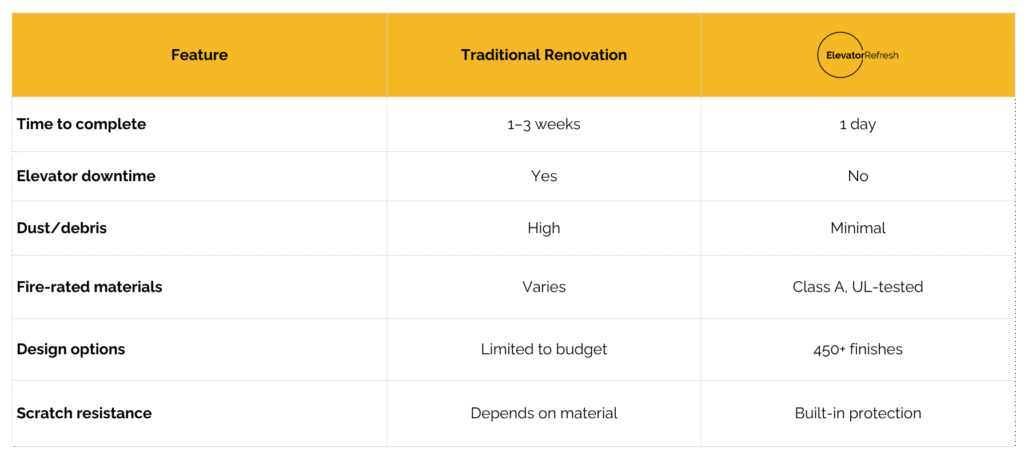

Benefits of Resurfacing vs. Replacing

How the Process Works

- Site assessment: We evaluate panel condition and help select an appropriate finish

- Cleaning & surface prep: We ensure adhesion by prepping existing surfaces

- Vinyl application: Skilled installers wrap each panel with precision

- Final check: Inspection and touch-ups before reopening

Most elevators are ready the same day, with no permits, no construction, and no disruption.

Final Thought: Small Scratches, Big Opportunity

Don’t let surface damage drive a full renovation. If your elevator is structurally sound but visually worn, a vinyl resurfacing is the smart choice.

It’s faster, cleaner, safer, and significantly more affordable.

Ready to eliminate scratches for good? Contact Elevator Refresh for a free consultation or samples of your choice.